One batch of drilling mud centrifugal pump and shear pump are ready for delivery to Europe client.

Common Applications of centrifugal pumps on a Drilling Rig:

1.Feeding Solids Control Equipments: it works as feeding pump of desander cone and desilter cone

2.Mud Mixing and Agitation: Transferring drilling mud from a storage tank to a mixing hopper to add new bentonite or chemicals, or circulating mud in a pit to prevent settling.

3.Supercharging: Acting as a “charge pump” for the main triplex mud pumps. It provides a positive pressure at the suction of the main pump, preventing cavitation (a major cause of damage) and improving the main pump’s efficiency, especially when pumping dense muds.

4.Transfer and Loading: Moving mud from one tank to another or loading/unloading mud from supply boats or trucks.

Key Operational Considerations of the centrifugal pump:

• Proper Priming: The pump must always be flooded (full of liquid) before start-up. Running it dry will destroy the mechanical seal almost instantly.

• Wear Monitoring: Operators must regularly monitor the pump’s discharge pressure. A drop in pressure indicates that the impeller and/or volute liner are wearing down and need replacement.

• Cavitation Prevention: A “gurgling” sound and erratic pressure indicate cavitation, which is caused by a restricted suction (e.g., a clogged strainer or closed valve). This must be corrected immediately.

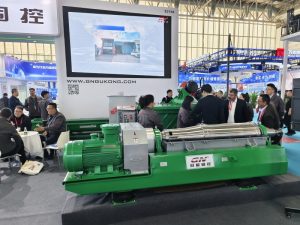

The features of GN shear pump:

1. It significantly enhance the hydration of moving soil particles

2. The shearing pump can provide shear efficiency accelerating the dilution and hydration of polymers.

3. It can make polymer shear dilution and hydration as soon as possible.

4. It can provide high discharge and head of delivery, which can meet the requirement of preparing and treatment of the drilling mud.

If you need other types pumps such as vacuum pump, submersible slurry pump, pls contact with GN solids.