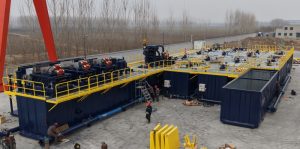

Recently one set of 2000HP Drilling Rig Solids Control System for Indian Drilling Company, this is the repeat order from the drilling company, they already purchased one set of 3000 HP rig solids control system. The features of the 2000HP rig solids control system including:

1. Single mud tank modular is interchangeable for both 2000HP mud tank system and 3000HP mud tank system, which allow the client to use it flexible for different projects.

2. The solids control equipments are interchangeable for both 2000HP solids control system and 3000HP solids control system, including the voltage/frequency/model/specifications, so the client can replace them if required.

3. The cable wiring connection and design is also interchangeable for both system.

The technical configuration of the 2000HP rig solids control system is as below:

1. Mud gas separator GNZYQ1200A, 1 ea

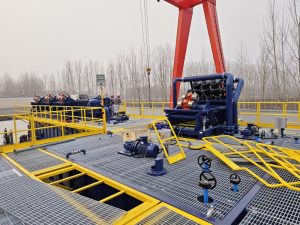

2. Drilling fluids shale shaker GNZS594K, 3ea

3. Vacuum degasser GNZCQ270B, 1ea

4. Linear motion mud cleaner GNZJ594K-2S12N, 1ea

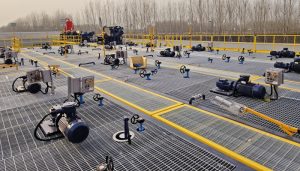

5. Mud mixing skid, including 2ea mixing hopper, 1 ea jet shearing unit and 2ea of 100HP mixing pump , which is connected to mud tank, it can suck from any compartment to mix the drilling fluids and also discharge to any of the compartment.

6. Mud tank system with pipelines, accessories, fittings, including shaker tank, intermediate tank, suction tank, trip tank, pre-flush tank, 3ea reserve tank, 3ea water tank, the total volume can meet the client’s requirement.

7. feeding pump of Desander, desilter , 2ea

8. Decanter centrifuge with feeding pump

9. Mud agitator and mud gun with proper model and qty for all the mud tanks to meet the requirement

10. Lightings and ATEX explosion proof electrical control system for the whole solids control system

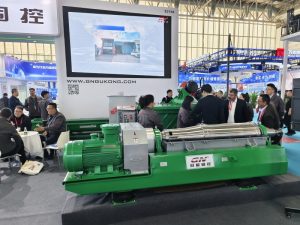

If you need a good quality, good performance drilling rig solids control system, pls contact with GN solids sales.