GN Solids Control is an international company with its solid control and waste management business spanning all around the world. Established in 2007 in China, it’s always striving to provide the good quality product to the customer and help them saving cost. In 2014, GN Solids Control subsequently established its overseas office in US and Russia, to better serve the local customer and provide them the quick delivery and excellent after sales service. Now GN not only manufacture every single solid control equipment, but also can provide the customers with solutions and solid control system.

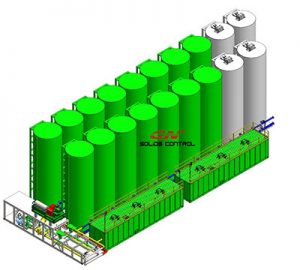

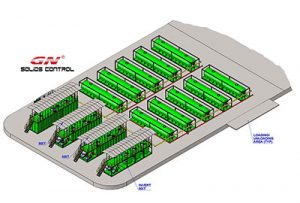

The liquid mud plant is one of its systems which mainly used in onshore or offshore to keep the mud properties as good as possible during the mud is circulating in the wellbore. The liquid mud plant is mainly composed of the following equipment, shale shaker, mud agitator, mud gun, centrifugal pump, mud mixing hopper, decanter centrifuge and various kinds of mud tanks. The type of mud tanks includes oil based mud tank, water based mud tank, base oil tank, barite tank, water tank, mud mixing tank and bulk tank. Each tank has its own special functions and will be deployed in different operation situations. Now GN can design and make different shapes and sizes of tanks, such as the round tank, vertical tank and rectangular tanks. The different sizes of liquid mud plants will apply the different sizes of tanks. The liquid mud plant is used to mix, dilute, treat, and adjust different kind of drilling fluids and make sure the fluids can meet the drilling standard and applied great into the well.

That’s the basic introduction of the liquid mud plant. Hopefully it will be useful to you. GN has many more solid control systems, they can be used in different operational situations and help you achieve your target easily and cost effectively. Welcome to visit www.gnsolidsamerica.com and please send your inquiries to USA@gnsolidscontrol.com

Month: July 2016

Introduction of GN’s vacuum degasser

GN Solids Control is a world famous company specializing in manufacturing drilling mud solid control and waste management and recycling. Its product range covers shale shaker, desander, desilter, vacuum degasser, decanter centrifuge, cutting dryer, centrifugal pump, screw pump and so on. Its products are mainly used in oil and gas drilling, civil works(like piling, TBM, HDD), and mining industry.

In the oil and gas drilling application, there is one important equipment in the solid control system, that is vacuum degasser. It is usually used after the shale shaker and before the mud cleaner. The main application of the degasser is to eliminate the gas immersed in the drilling mud, which will help restoring the mud weight, stabilizing the slurry viscosity, reducing the drilling cost, and preventing the well blow out accident. The vacuum degasser is mainly composed of vacuum tank installed on a skid base, vacuum pump, gas water separator, control panel, explosive proof motor. Its working principle is that: under the effect of the suction power from vacuum pump, negative pressure zone will be generated in the vacuum tank, and the drilling mud will enter the hollow shaft of the rotor through the suction tube under the effect of the atmospheric pressure. Then the mud will hit the windows of the hollow shaft and be sprayed to the wall of vacuum tank. Under the collision effect of the separation baffle, the mud will be separated into thin layers, and bubbles immersed in the mud will be broken up and comes out. The gas will be discharged by the vacuum pump and gas water separator to the safe zone, the mud will be discharged outside of the tank by impeller. In the whole process, the rotor will keep running at high speed under the power of main motor.

Now GN has two kinds of vacuum degasser: GNZCQ270A and GNZCQ360A, the processing capacity for these two equipment is 270m3/h and 360m3/h. Welcome to visit www.gnsolidsamerica.com and please send your inquiries to USA@gnsolidscontrol.com

GN’s 930 cutting drying-the star product in the solid control and waste management system

GN solid control is a world famous company in the solid control and waste management area. Since established in 2007, it has already set up a full and mature product line in the solids control area, such as the shale shaker, desander, desilter, mud cleaner, decanter centrifuge, cutting dryer, centrifugal pump, screw pump, agitator and so on. GN can be your No. 1 choice and one stop shop in the solids control business.

Among all of GN’s products, one of them is the star product, that is cutting dryer. No matter in the flow line for solid control or for waste management, it has shown great performance. There are two types of cutting dryer, fixed speed and VFD. GN can manufacture them according to different customer’s requirements and save money for customers. The screen bowl’s maximum diameter is 930mm. And there are three different kind of screens for your choice, 250 micron, 350 micron and 500 micron. The handling capacity is 30 to 50 tons per hour. Tungsten carbide protect the flights on the rotor from abrasive solids and ensure longer operation life. The special design of high pressure air knife can clean the basket screen automatically and easily, and avoid the screen to be blinded by the viscosity mud and water based mud. The flushing system with specially designed nozzles around the body of cutting dryer can avoid the liquid discharge channel being blocked by sediments. The lubrication system is electrically interlocked with the main motor starter to prevent machine operation in the event of low or no oil pressure to the gearbox. The VFD control panel can facilitate soft starting, fingertip control of the VFD system can change the motor speed and thus the G force can be changed to the working conditions. The VFD system is made by ABB or SIEMENS and it is explosive proof.

The GN’s 930 cutting dryer can be used for handling water, oil or synthetic based mud. We will try our best to assist your business to be successful. Welcome to visit www.gnsolidsamerica.com and please send your inquiries to USA@gnsolidscontrol.com

GN’s solid control star product-GN363 Decanter Centrifuge

GN Solids Control is an integrated company for manufacturing the solid control system and waste management equipment and system. Established in 2007 in China, GN now has grown from a local Chinese company to an international company with its products sold to more than 60 countries. In 2014, GN set up its overseas subsidiaries in US and Russia to get closer to the local customer and better serve the local market.

Among all the GN’s product line, there are there main ones which are more reliable, mature and popular in the market, they are shale shaker, decanter centrifuge and cutting dryer. As one of the key components in the solid control and waste management system, decanter centrifuge plays an important role in the solid and liquid separation process.

Among the Decanter centrifuge’s different specification and configurations, GNLW 363C is the most popular and reliable, it is the star product. There are fixed speed centrifuge and VFD controlled centrifuge. There are many highlights about the equipment: the bowl material is made from duplex stainless steel 2205 which is made by centrifugal casting, and it’s much better than stainless steel 304 and stainless steel 316. The solid waste discharge port is protected by special ceramic inserts which is made by world famous manufacturer with longer and more endurable life. The adjustable effluent port make the pond depth adjustment easier and more convenient and fast. The pneumatic controlled spring will make the opening of the cover more easily and safely. During the transportation, the bowl lifting bracket can perform as the protection for the bearings. The bearings are made by the world famous SKF company. The two motors are placed at one side of the equipment and make it smaller footprint. The conveyor surface is made from Tungsten carbide tiles which is more endurable and easy for maintenance. The VFD system is provided by ABB or SIEMENS. ATEX and IEC EX for zone 1 control panel can be provide as request.

We will try our best to assist your business to be successful. Welcome to visit www.gnsolidsamerica.com and please send your inquiries to USA@gnsolidscontrol.com

Shaker screens in stock for sale in GN’s US warehouse

GN Solids America facility was first established in 2014 in Houston, TX. The facility is a multi functional with office, assembly center and spare parts center. The facility takes about 30,000 square feet. This office is the first overseas subsidiary for GN Solids Control and is performing the function as sales, after market service and warehousing.

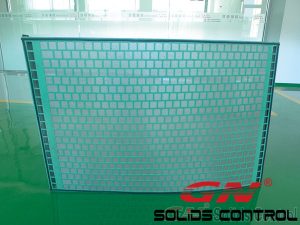

Now in GN Solids America warehouse, there is plenty of shaker screen in stock. There are many types of screen there, such as the GN own brand GNZS series, replacement screens for MI-SWACO MONGOOSE PRO, MONGOOSE PT and MEERKAT, ALS, BEM; replacement screens for DERRICK FLC 2000, FLC 500, DP 600, and hyperpool; replacement screens for NOV Brandt Cobra, King Cobra, Mini Cobra, Venom, LCM-2D, LCM-3D, VSM 300 series( include scalping, primary and secondary) and replacement screen for some other popular brand, such as Fluid System. GN Solids control can manufacture many types of screen, such as the composite frame, metal frame, soft hook strip and hard hook strip. The screen could be flat or pyramid according to customer’s requirement. The screen could be 2 layers or 3 layers depending on the customer’s requirement for the API number. The screen surface are made of stainless steel, usually use SS304 or SS316. This material can make the screen more endurable and work for longer time. GN can manufacture the screen from API 20 to API 400.

GN Solids Control’s 2nd manufacturing facility for shaker screen will soon be in production. It will be about to produce about 5000 pieces of screens annually. The screen frame will be mainly composite material. GN recommends our customer to use composite frame shaker screens because it’s lighter, has longer usage life, corrosion resistant and has larger non-blank area. Now GN screens have been sold to global market, we hope to get your inquiry soon.

Welcome to visit www.gnsolidsamerica.com and please send your inquiries to USA@gnsolidscontrol.com