The market is down, we are supplying

service with lower price, we are waiting for the contract. Another factory is

taking more days off. As the saying goes, the economic crisis is not only your

neighbour lost job, yourself is also being fired. Nowadays more and more

oilfield companies have been suffered hard days. And some may change business,

especially small companies, keep lower and lower price will never last too

long.

GN is mainly target on overseas market,

high quality equipment and reasonable price. GN Solids Control equipment

have taken lots of drilling site in Middle East, Africa, Russia, America,

Brazil, Australia etc.

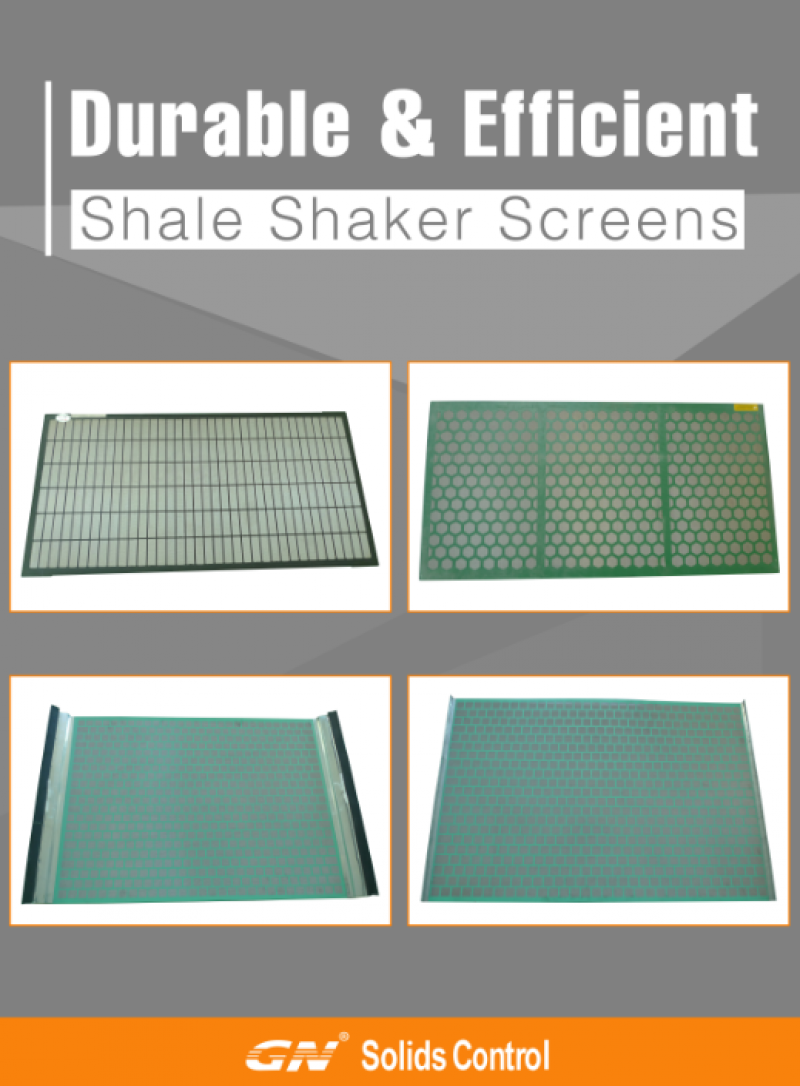

GN Solids

Control equipment including: shale shaker, shaker screen, mud cleaner,

desander, desilter, decanter centrifuge, mud agitator, mud

gun, centrifugal pump, screw pump, vertical

cuttings dryer, screw conveyor, High G drying shaker etc.

Keep focusing on solid liquid separation

equipment, making better solids control equipment, drilling

waste management equipment for oil drilling projects. For HDD,

environmental industry and so on. And this will be where we can make some differences,

from each and every details. So in the new year, we will still keep focusing on

the main equipment, and change the world.

Keep tune on GN Solids Control, in 2016,

we will have big improvement on shale shaker, decanter centrifuge, and cuttings

dryer. Also we will have our TDU thermal

desperation unit ready, well tested, and probably some early bird client will

use it on field. Looking forward a new challenging year.

More and more strict environmental

protection laws will require more TDU equipment, and GN TDU will be very

flexible, comparing a hug site. As in future, we can expect all waste

management work will be done on site. Not a long trip to a mud pit, and

transferred to a lot of equipment, and pumped from this to there. Find you most

convenient way to meet or discuss with GN Solids Control.