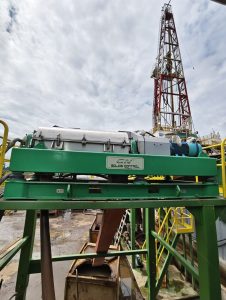

Recently 16 packages of GN solids control centrifuges are shipped to offshore drilling company, this is the repeat order from this client.

The offshore decanter centrifuge package including one centrifuge with feed pump and solids discharge trough, one offshore skid, one fluids catching tank and transfer pump, one offshore used VFD control panel. All of the equipments are installed as compact unit for offshore application, the skid and decanter centrifuge lifting pad is designed comply with DNV 2.7-1 standard.

The decanter centrifuge motor and VFD control panel is adopted with offshore applied explosion proof standard. The ambient temperature to be used is -20℃ to +55℃.The standard atmospheric pressure is 80 Kp to 110Kp, normal oxygen content 21%, it can be used with altitude <1000m, relative humidity less than 95%. One centrifuge is composed of main bowl assembly, power drive system, feeding and discharge device and electrical control system.

The decanter centrifuge is widely used in the solids control and drilling waste treatment project, it works to separate the solids phase from drilling fluids, remove the harmful fine drilling solids such as debris in the drilling mud, or recover weighting materials such as barite , etc. as to save the drilling fluids cost. The decanter centrifuge can be used for both onshore and offshore projects, but the electric motor, control panel including VFD control panel, cables standard are different.

GN solids control can produce 9 inch bowl centrifuge, 14 inch bowl centrifuge, 18 inch bowl centrifuge, 22 inch bowl centrifuge, 30 inch bowl centrifuge, each size decanter centrifuge provides 2 models as rated frequency and variable frequency drive. Except for 2 phase decanter centrifuge, we also produce three phase decanter centrifuge to separate oil, solids and water for oily waste water treatment.

If you need a decanter centrifuge package, pls contact with GN solids control.