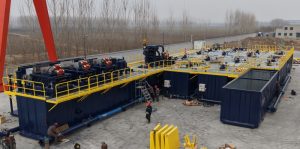

Recently one set of 750HP Workover Rig Solids Control System are ready for delivery to China oilfield service company.

The typical features of 750 HP rig including:

1.Compact Layout: Designed for skid-mounted or trailer-based mobility.

2.Automation: Modern systems may include PLC controls for optimized performance.

3.Adaptability: Handles oil based mud (OBM), water based mud (WBM), and synthetic based mud (SBM).

The solids control system including the items below:

1) One set of mud tank system, customized dimension as client’s requirement, including shaker tank, mixing tank, trip tank, each tank equipped with mud agitator, mud gun, lightings, mud tank accessories.

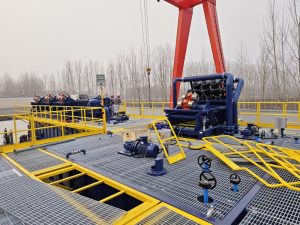

2) 2 sets of drilling fluids shale shaker GNZS594K, GNZS594K shale shaker is the lastest version linear motion shale shaker produced by GN solids control, it is a 4 panel shale shaker installed 4pcs of 585x1165mm composite material frame shaker screen. The shale shaker is drived by 2ea 2.6HP vibration motors, the max G force is 7.5G and it is adjustable.

3) 1 set of mud cleaner GNZS594K-2S12NK, it is desander, desilter, shale shaker 3 in 1 combination mud cleaner, the 10 inch desander cone qty is 2ea, the 4 inch desilter cone qty is 12 ea, the treating capacity of the mud cleaner is 1000gpm, 2ea centrifugal pumps are installed on the tank skid as feeding pump of the desander cone and desilter cone.

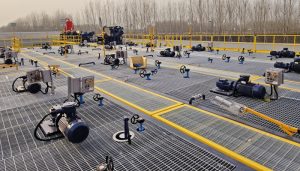

4) 1 set of middle speed decanter centrifuge GNLW452D, it has been widely used for barite recovery. If you need to separate the low gravity solids further, we can use GNLW363 or GNLW363-VFD decanter centrifuge.

5) Centrifugal pumps, mud agitator, mixing hopper, mixing pump, electric control system, etc.

If you need a customized design and high quality high performance drilling rig solids control system, pls contact with GN solids control for more information.