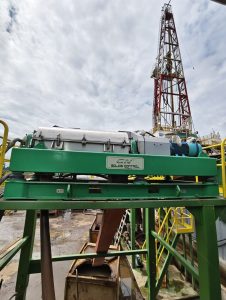

One set of GN decanter centrifuge and vertical cuttings dryer are using for Africa drilling company. The equipments list including:

2 units of decanter centrifuge,model GNLW363D-VFD

1 unit of vertical cuttings dryer,model GNCD930G

Matched with screw conveyor, centrifuge feeding pump and vertical cuttings dryer flushing pump.

The screw conveyor GN produced including 10 inch, 12 inch, 14 inch, 16 inch and 18 inch diameter for option, each section standard length is 12 ft, we can use different quantity sections as per client’s requirement of transfer length, such as 12 ft, 24 ft, 36 ft, 48 ft, 2 sections are connected by pin shaft hanger. The screw conveyor can be fixed speed or variable speed( manually speed adjustable) to control the feeding rate. The screw propeller material is High Chrome Alloy Steel for longer working life.

According to the installation position and function of the screw conveyor, there are auger system for primary shale shaker discharge solids collection, desander desilter discharged solids collection, feeding to vertical cuttings dryer feed hopper, solids discharge auger for vertical cuttings dryer, solids discharge auger for decanter centrifuge, etc. The protection cover on the U type reinforcing beam could be closed steel plate or steel grating for option.

Additional safety protection of the screw conveyor:

1) Pull chord emergency stop with wire rope to be provided along the length of Augur for Emergency stop;

2) Audio / visual alarm system on the auger control panel which will be automatically activated once the power is switched on followed by the actual auger startup with a safety delay time. Audio / visual alarm system to be in the OFF mode after some time once the auger starts operation.

If you need decanter centrifuge, vertical cuttings dryer, feeding pump, screw conveyor, pls contact with GN solids control.