drilling waste management separator may be the very first phase expert gear to deal with the actual gasoline get into dirt. drilling waste management is primarily accustomed to take away the large pockets using the size around 3mm. Many of these pockets would be the broadened gasoline stuffed within the drilling waste management within annular associated with wellbore. It might trigger nicely stop in the event that mot to get rid of this well-timed.

Procedure theory from the separator

drilling waste management along with gasoline invades adopts the actual separator in the transfer tangentially

as well as falls to some sequence baffles across the internal walls. Following crash in order to growing the actual get in touch with region, This moves downwards and be to some violent condition making gasoline individual through dirt and also the free of charge gasoline goes by with the best associated with tand as well as released in the gasoline foreign trade. Along gasoline foreign trade tube could be decided from website as well as w at the imduced towards the secure location. The actual drilling waste management without having gasoline may circulation to the round container.

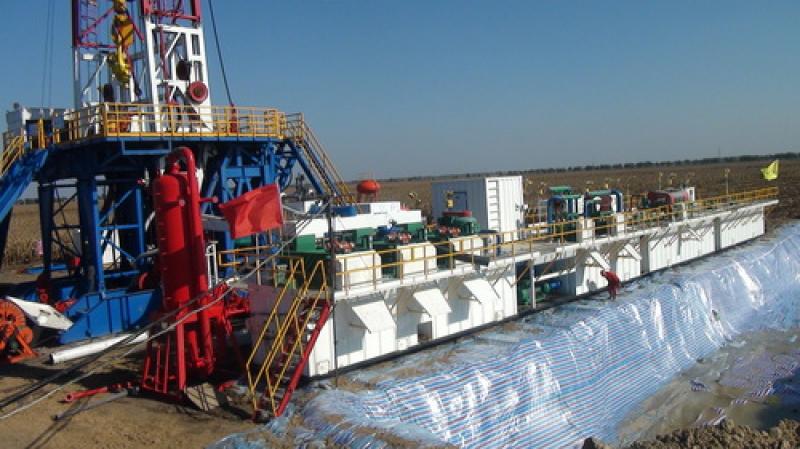

GN Solids Manage is among the top producer within The far east with regard to solids manage equpment such as drilling waste management . You will find 3 types of Drilling waste management ZYQ900, ZYQ1100 as well as ZYQ1300 would be the primary with regard to gas and oil drilling rig solids manage in order to employed by 2000m, 3000m, 4000m, 5000m or even 7000m drilling rig solids manage program. Besides drilling waste management GN additionally provide shale shaker, desander, desilter, centrifugal pump motor, decanter centrifuge, dirt agitator, combining hopper, dirt container and so forth associated with regard to drilling waste management program. Click the website to know more information.